Surface Treatments

Surface Treatments

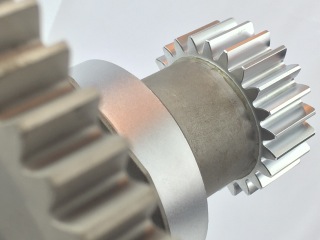

Metals are treated to change their surface properties for: decoration and reflectivity, improved hardness and wear resistance, corrosion prevention and as a base to improve adhesion of other treatments such as dry films, paints, or powder coatings.

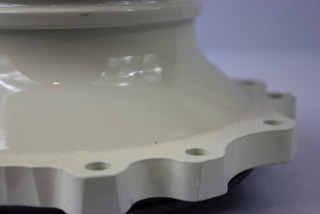

Protective Coatings

Protective coatings are coverings that are intended to provide a layer of protection from anything that could damage the function or integrity of a component or part. In all instances, the main function of protective coatings is to allow a part to remain in good condition for a prolonged period of time. Protective coatings make it possible for many parts to last longer than would be possible if no coating was applied.

Protective coatings are coverings that are intended to provide a layer of protection from anything that could damage the function or integrity of a component or part. In all instances, the main function of protective coatings is to allow a part to remain in good condition for a prolonged period of time. Protective coatings make it possible for many parts to last longer than would be possible if no coating was applied.

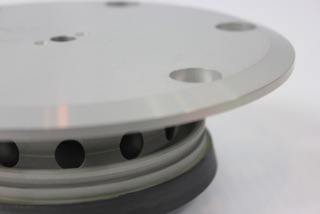

Plating

Electroless plating is metal deposition by a controlled chemical reaction. In contrast to an electroplating solution, electroless solutions (e.g. Electroless Nickel) require no external source of current to plate. The process utilizes a chemical reducing agent incorporated into the solution and provides a continuous build-up of deposit, since the metal being plated is itself a catalyst for the plating reaction. This process is also known as autocatalytic plating.

Electroless plating is metal deposition by a controlled chemical reaction. In contrast to an electroplating solution, electroless solutions (e.g. Electroless Nickel) require no external source of current to plate. The process utilizes a chemical reducing agent incorporated into the solution and provides a continuous build-up of deposit, since the metal being plated is itself a catalyst for the plating reaction. This process is also known as autocatalytic plating.

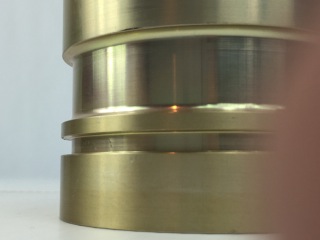

Electroplating is the application of a metal coating to a metallic or other conducting surface by an electrochemical process. The article to be plated becomes the cathode (negative electrode) in an electrolysis cell through which a direct electric current is passed. Articles are electroplated to (i) alter their appearance; (ii) to provide a protective coating; (iii) to give the article special surface properties; (iv) to give the article engineering or mechanical properties.

- Cadium Plating

- Chrome Plating

- Electroless Nickel Plating

- Nickel Cadium Plating

- Nickel Plating

- Silver Plating

- Zinc Nickel Plating